Agentic AI in Finance & BFSI : Real Use Cases Worth Watching

Build a Connected, Insight-Driven

Industrial Enterprise

Drive resilient, data-driven production and supply chain excellence with Oracle Manufacturing solutions.

Oracle for Industrial Manufacturing

Trusted by Leading Manufacturing Innovators

Global industrial enterprises rely on Oracle and AppsTek to modernize operations, improve agility, and scale growth.

Trusted by Manufacturing Enterprises

Why Industrial Margins are Under Strain

With rising disruptions and tighter margins, inefficiencies are costly. Industrial manufacturers need a partner who transforms constraints into strategic advantage.

01

Supply Chain Volatility

Unpredictable lead times and material shortages expose the limitations of rigid legacy ERPs that cannot adapt.

02

Shrinking Profit Margins

Rising material and energy costs strain profitability, and outdated costing systems cannot keep pace.

03

Talent Gaps and Skill Drain

An aging workforce puts critical knowledge at risk, and manual processes cannot preserve expertise.

04

Legacy System Fragmentation

Disconnected systems create blind spots and delays, making coordinated, real-time operations impossible.

05

Stalled Industry 4.0 Efforts

Most pilots never scale because siloed data and legacy infrastructure block enterprise-wide adoption.

06

Rising Compliance Pressures

Expanding ESG and reporting mandates overwhelm teams that rely on spreadsheets and fragmented tools.

Strategic Priorities for a Smarter Manufacturing Future

The focus is now on scaling digital foundations to handle complexity, mitigate risk, and unlock new revenue models, making every operation responsive and predictive.

Establish

a Digital Core

Modernize core ERP/SCM on a unified cloud platform to enable data-driven decisions and standardized global processes.

Fortify Supply Chain

Resilience

Proactively mitigate risk using real-time monitoring, diversified sourcing, and demand-sensing intelligence.

Scale Smart

Manufacturing

Boost Overall Equipment Effectiveness (OEE) with connected machines, predictive maintenance, and shop-floor automation.

Cultivate a Tech-Enabled Workforce

Bridge the skill gap by using connected worker tools and structured training for digital adoption.

Pivot to

"X-as-a-Service"

Develop new, recurring revenue streams by offering usage-based models and value-added aftermarket services.

Achieve Sustainable

Production

Embed traceability and resource optimization into production to meet regulatory and environmental goals.

Empowering Manufacturing Leaders

Across the Value Chain

Oracle solutions deliver the insights, automation, and visibility leaders need to streamline decisions, improve efficiency, and unify end-to-end operations.

CIO

Enable unified cloud platforms that deliver scalable, secure, and data-driven enterprise operations.

Head of R&D

Launch products faster with connected PLM, real-time costing, and seamless transfer to manufacturing.

COO

Improve efficiency by standardizing global workflows and automating complex production processes.

Supply Chain Director

Strengthen continuity with real-time risk sensing, predictive planning, and coordinated global logistics.

Plant Manager

Enhance plant performance with predictive insights, connected monitoring, and Vision AI-driven quality control.

CRO / Service Lead

Grow service revenue using connected asset data and IoT insights for proactive, high-margin service delivery.

Oracle Expertise Built for Your Industrial Reality

Generic solutions fail in complex manufacturing. We tailor the Oracle digital core to your compliance, supply chain, and production needs across ETO and high-volume operations.

- Industrial Machinery & Equipment

- Food and Beverage Processing Equipment

- Automotive Components

- Heavy Machinery & Capital Goods

- Electrical Equipment & Controls

- Metal, Plastics, Rubber & Fabrication

Design-to-Maintenance Control

- Mission-Critical Focus Areas: Managing long engineer-to-order (ETO) workflows and high-variance BOMs while guaranteeing asset reliability.

- Our Implementation Focus: Integrating PLM, ERP, and Maintenance Cloud to enable real-time cost tracking and streamline ETO processes.

Designed to Run Right

- Mission-Critical Focus Areas:Hygienic design, configured-to-order machinery, precise batch execution, and regulatory compliance.

- Our Implementation Focus: Utilizing digital twins for design accuracy and ensuring full batch traceability and service uptime reliability.

Built for Moving Targets

- Mission-Critical Focus Areas: Just-in-Time (JIT) delivery, high-precision quality standards, strict traceability, and rapid engineering changes.

- Our Implementation Focus: Synchronizing supply/demand planning and automating real-time quality and traceability to meet OEM mandates

Lifecycle Control at Industrial Scale

- Mission-Critical Focus Areas: Large, long-lifecycle assets requiring complex assembly, global sourcing, and rigorous project cost tracking.

- Our Implementation Focus: Connecting the asset lifecycle to optimize long-horizon production plans and enable profitable predictive maintenance.

Control Across Every Module

- Mission-Critical Focus Areas: Tight quality assurance, complex modular BOMs, and rapid configuration for varied customer needs.

- Our Implementation Focus: Digitizing engineering change control and integrating design with production execution for speed and accuracy.

Production Without Pileups

- Mission-Critical Focus Areas: Material efficiency, scrap reduction, accurate costing, and energy-efficient, high-throughput production.

- Our Implementation Focus: Tracking material consumption in real time and optimizing shop-floor sequencing to reduce scrap and energy use.

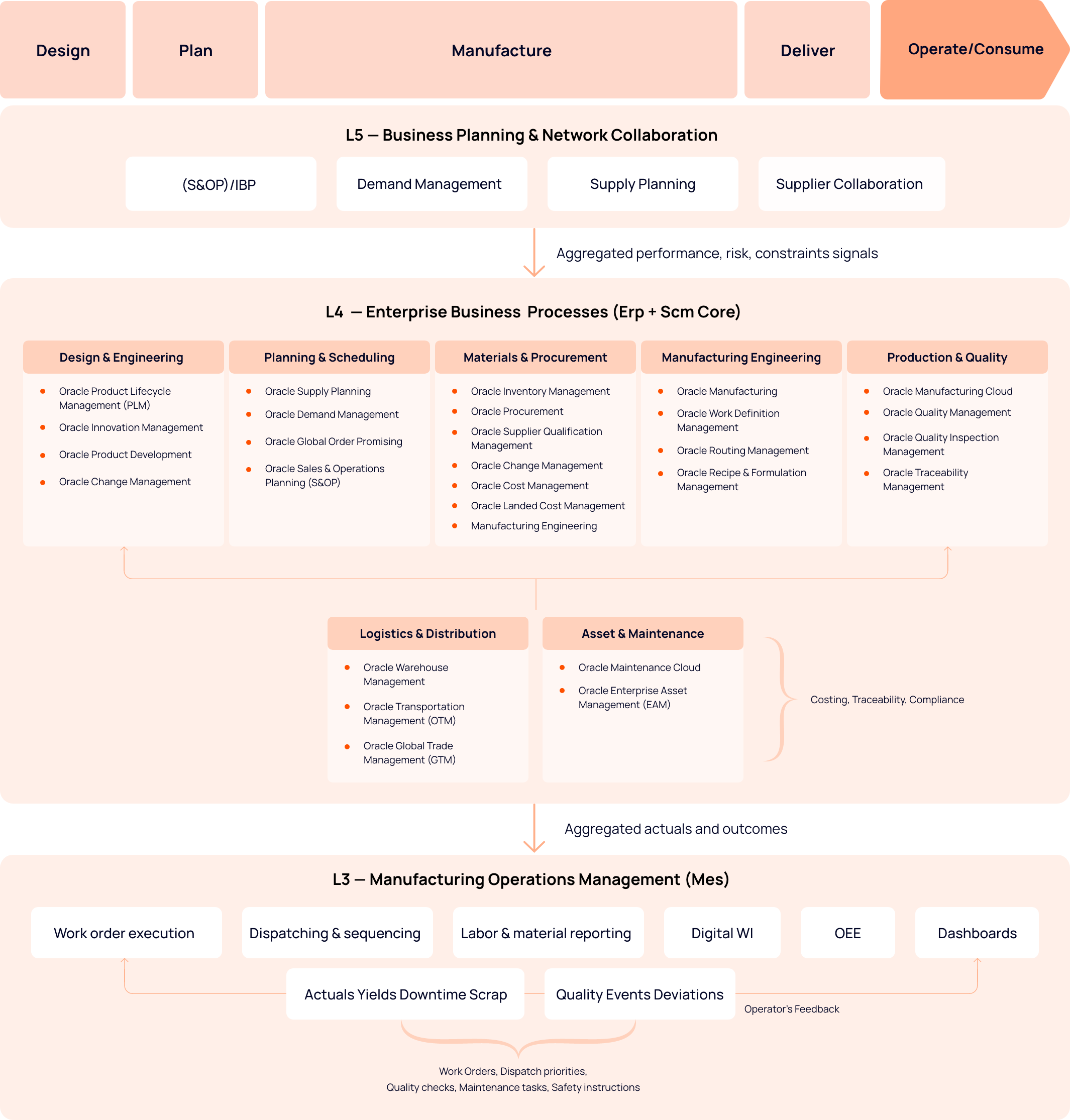

Orchestrating Industrial Manufacturing

Lifecycle From Design to Operate

Transform planning, production, and maintenance with connected data, autonomous workflows, and Industry 4.0 intelligence.

Adaptable to diverse production models

See how Oracle modernizes planning, execution, quality, and maintenance

Agentic AI for Autonomous Manufacturing Operations

Oracle infuses AI agents into manufacturing and supply-chain workflows to automate tasks, surface insights, and enable faster, more resilient operations.

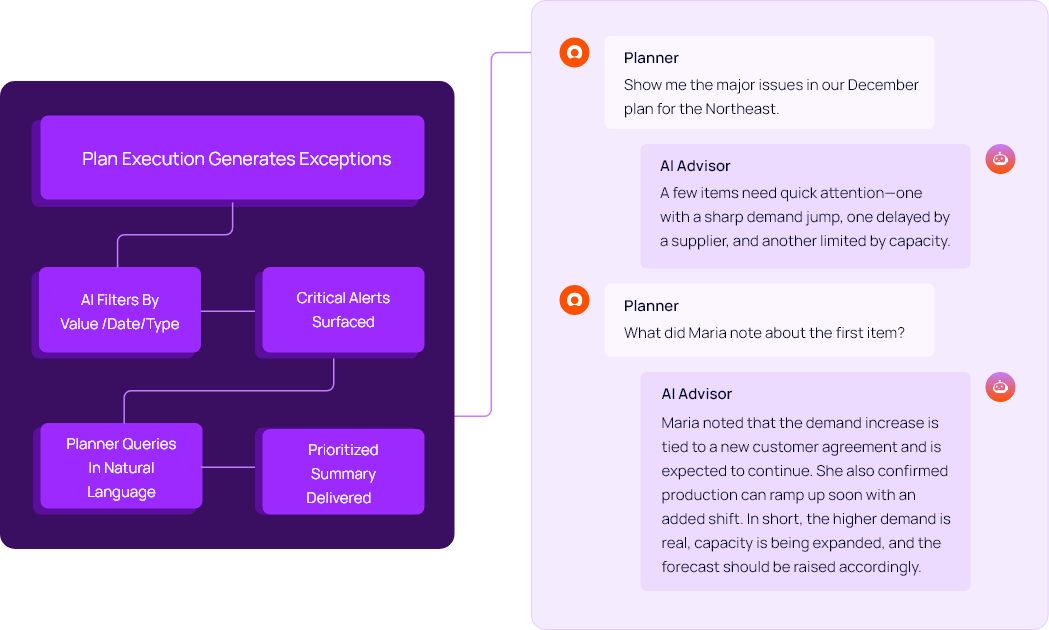

- Planning Advisor for

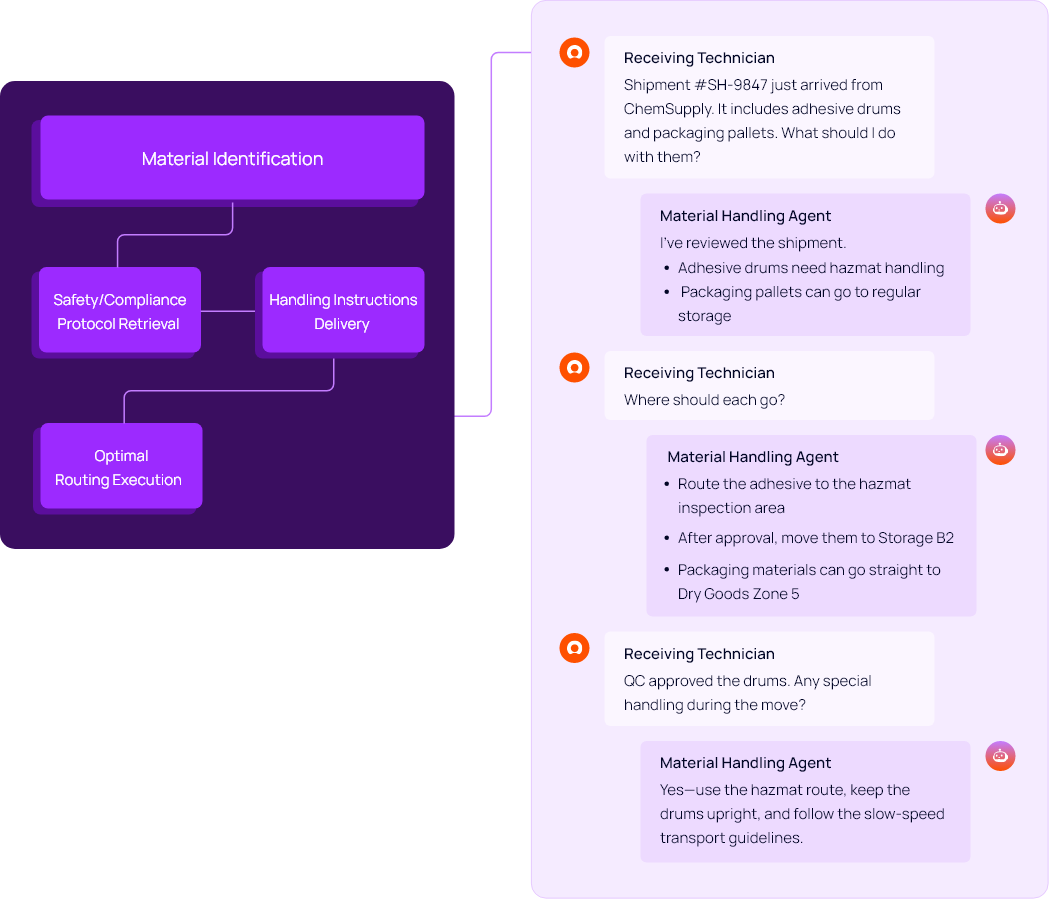

Exceptions & Notes Agent - Material Handling

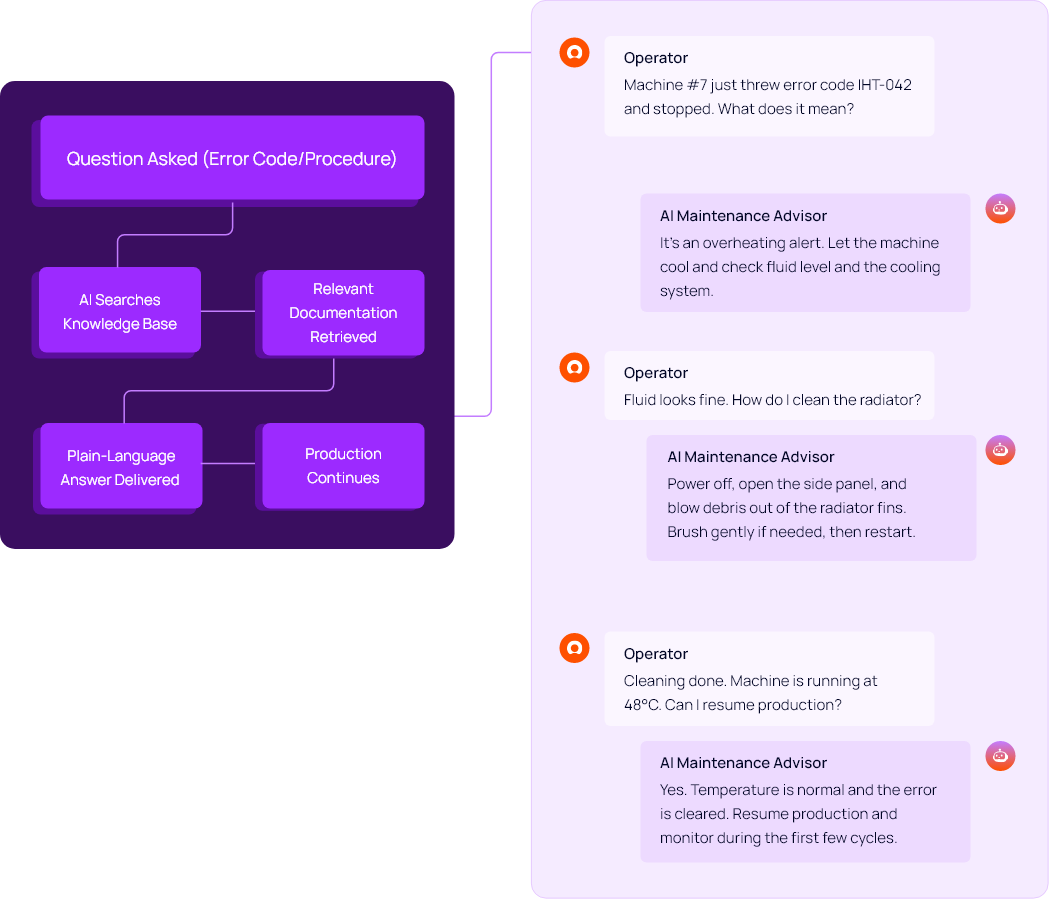

Advisor Agent - Maintenance

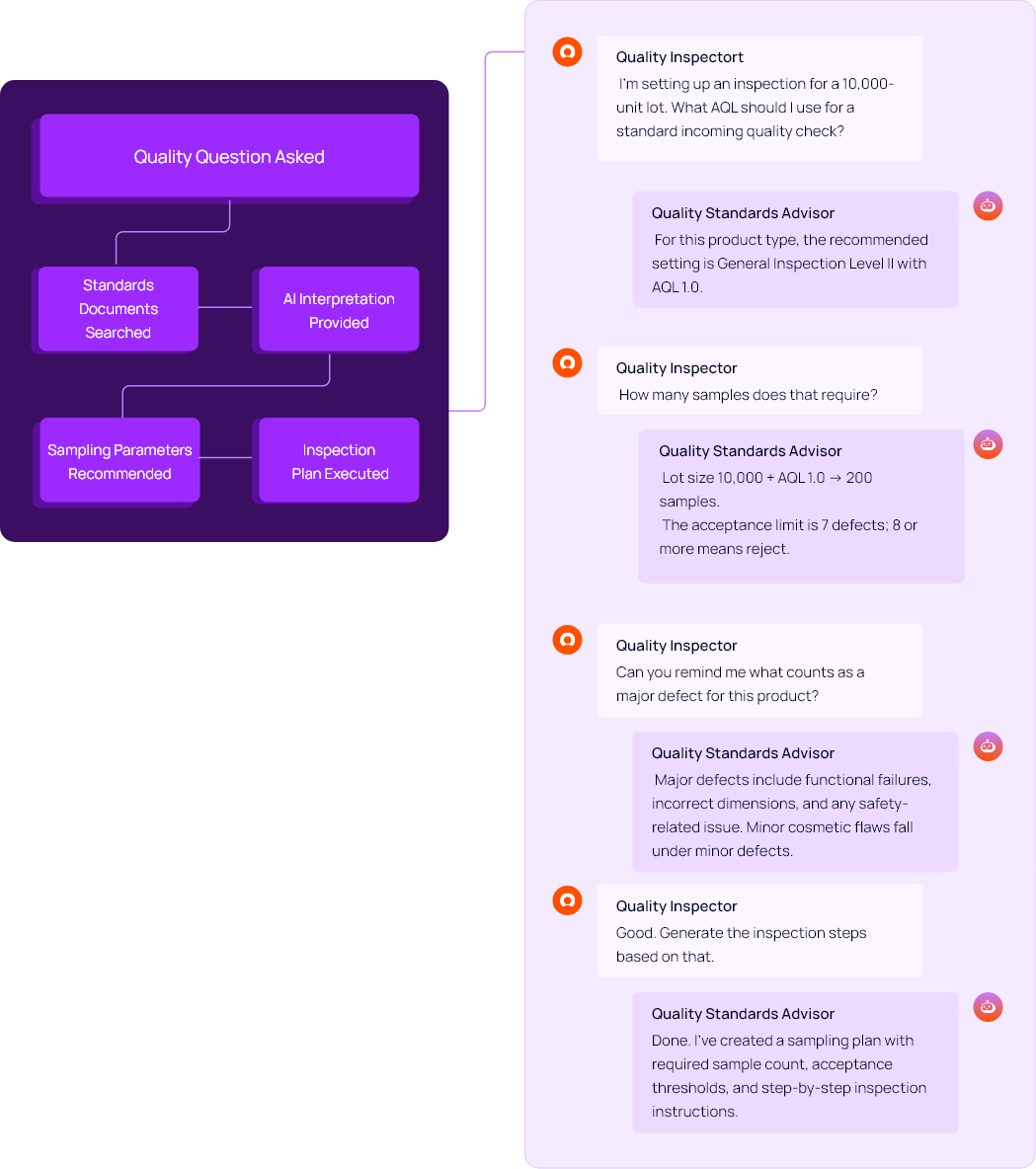

Advisor - Quality Inspection

Standards Advisor Agent

What it does

Pinpoints the most important planning issues and notes through simple queries. Delivers clear, prioritized insights so teams make decisions faster without digging through reports.

Value

Speeds up exception analysis, improves planning accuracy with quick, natural-language insights

What it does

Provides real-time guidance to receiving teams for safe, compliant handling of incoming materials.

Value

Zero compliance violations, increased speed, reduced damage, improved safety

What it does

Provides quick, plain-language answers to safety, equipment, and procedure questions on the factory floor.

Value

Faster information retrieval, reduced downtime, improved safety, better consistency

What it does

Provides fast, AI-driven answers to quality standards and inspection requirements.

Value

Faster standards lookup, improved compliance, reduced training time, consistent quality

Accelerate Industrial Manufacturing Transformation

with AppsTek Services

Transform operations with Oracle EBS, Fusion, OCI, Analytics, and AI, supported by accelerators for rapid deployment, automation, and data-driven plant performance.

Accelerators that Modernize and Scale

Oracle for Industrial Manufacturing

A unified suite of tools that automate workflows, standardize processes, and enable real-time decision-making across plants, supply chains, and financial operations.

Intelligent Engineering Document Control for Manufacturing Operations

Apply AI to classify, extract, and govern engineering drawings, work instructions, and compliance documents across plants and teams—delivering faster access, stronger control, and lower compliance risk.

AI-Driven Service Lifecycle Intelligence for Industrial Assets

Apply AI to interpret service contracts, warranties, and maintenance obligations and connect them directly to execution across the asset lifecycle, improving service performance, reducing leakage, and increasing asset uptime.

ENERGY & UTILITIES SUCCESS STORIES

Proven Wins with Oracle Solutions for Industrial Manufacturing

See how leading industrial manufacturers modernize planning, quality, and operations using Oracle solutions.

AUTOMOTIVE & MANUFACTURING

Modernizing Procurement with Oracle Redwood UX

Elevating procurement efficiency and user experience for a global manufacturing R&D division.

CHEMICAL MANUFACTURING

Modernizing Production Planning with Oracle OPM & MRP

Improving batch planning, material availability, and operational control for a global chemical enterprise.

INDUSTRIAL MANUFACTURING

Streamlining Enterprise Operations with Oracle E-Business Suite

Enhancing system performance and process efficiency for a global industrial solutions provider.

METALS & STEEL MANUFACTURING

Transforming Core Operations with Oracle E-Business Suite

Enabling standardized, scalable enterprise operations for a large steel manufacturing organization.

Explore Solutions for Industrial Manufacturing

Adaptable to diverse production models