Vehicle Route Optimization (VRO) remains a common problem for all organizations having fleets. The objective being to decide an optimal route servicing multiple customers while minimizing the cost and the number of vehicles used.

We were approached by a facilities management company which manages waste and waste-water for its customers. The scale was to manage around 900,000+ tons of waste per annum with 400 vehicles and over 3500 customers ensuring the following business pains were addressed:

- Complete automation in handling customer orders

- Reduced mileage by determining the shortest route

- Optimum utilization of vehicles

- Considering diverse vehicles and waste categories

- Effective time management of their mobile workforces servicing the customers

- Capability to handle Adhoc orders

- Live GPS tracking

- Customer Satisfaction

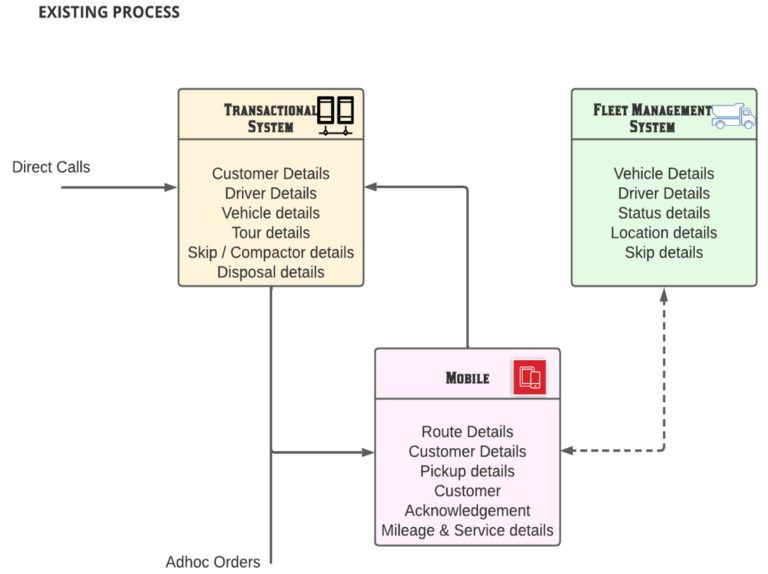

The existing process followed was completely manual with the organization receiving customer calls and entering the same into their transactional system to generate work orders. Once the work order was created, the details were passed to their field service team through the mobile app to schedule the customer visit.

The fleet management system kept a track of all the vehicles, the driver details, locations and the skip / compactor (waste bins) details. There were different kind of vehicles used for different waste categories and all of these were managed by the system.

Finally, the right vehicles were identified and the customer visits were scheduled. Incase of Adhoc orders, the vehicles were tracked by their GPS location and calls were made to the driver of the respective vehicles to accommodate such requests depending on the vehicle’s proximity to the customer location. Manual planning and last-minute scheduling of Adhoc orders, resulted in more vehicle mileage, ineffective utilization of vehicles and in majority of the cases, considerable delays were observed while handling customer requests.

The organization was spending a lot of money not only for the above reasons, but also had limited visibility in terms of Estimated Time of Arrival (ETA) and Estimated Time of Delivery (ETD) while servicing the customers, ultimately leading to customer dissatisfaction.

The other factors that also had a considerable impact were increased fuel cost, higher vehicle servicing and maintenance cost and a hit on the depreciation value considering the fleets they manage.

Our Solution approach involved a careful consideration of the following parameters:

- Optimal route and resource allocation for waste collection over different sets of hubs

- Overall fleet of vehicles comprising of Skip Trucks, Compactors and Roll-on / Roll-off Trucks

- The location to be serviced by different hubs

- API calls made to extract road distance between locations as well as typical time required to run between them

- Separation of location sets based on hub sets as well as vehicle types and service bin types

- Optimization directed to different sets of routes: Each for skips / compactors and for different hub sets

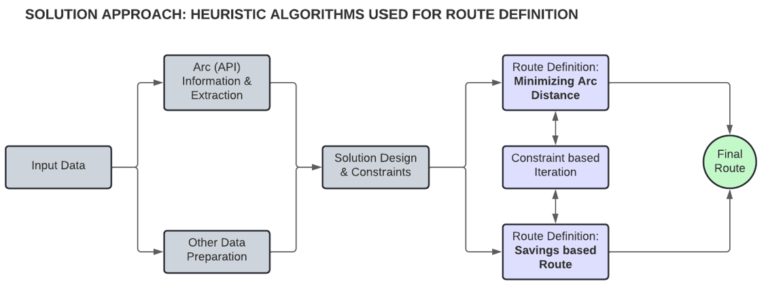

- Use of constructive Heuristic Algorithms to develop efficient routes as shown below:

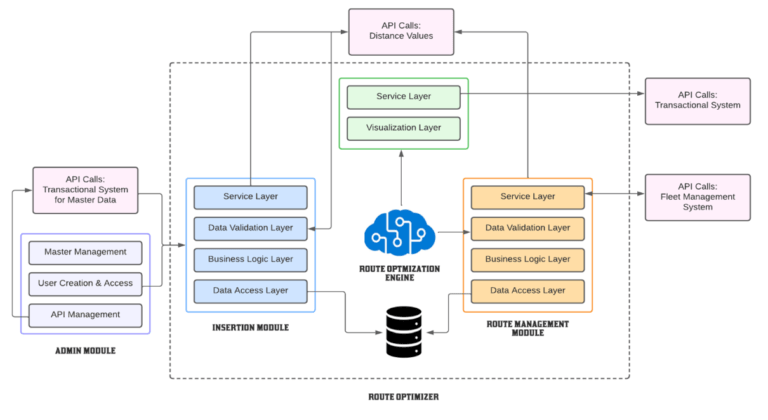

The organization wanted an automated solution that would integrate with their internal systems and display the results on the Mobile App, so as to assist and guide their workforces to follow the exact route for the customer’s to be serviced on a given date.

Integrations required included API calls to Transactional system for both Master Data and Work order information, API calls for Distance values and lastly API calls to Fleet management system to get the GPS locations of vehicles used in carrying the waste. Technical Architecture to fulfil the above requirements is given below:

Benefits helped the organization achieve the following:

- Reduce fleet mileage (actual distance travelled)

- Optimize resource utilization (both – vehicle & driver)

- Tracking of ETA and route completion (i.e., ETD)

- Reduce cost & Improve Operating Efficiency

– Fuel & Maintenance cost

– Overtime

- Reduce Carbon footprint

- Revenue Maximization

– Driver efficiency Optimization

– Value added Services

- Customer Satisfaction (Quality of Service – QoS)

– Timely pick-ups

– Conducting surveys

Hence a VRO solution can be extended to service any organization that manages fleets such as:

- Delivery Services – Can be delivery of Food / Essential Supplies etc.

- Manufacturing – involved in delivery of Industrial goods / services of any kind

- Logistics – such as Courier delivery services

- Retail – delivery of Retail goods to customers

- External Agencies – who provide Transportation services of these kind

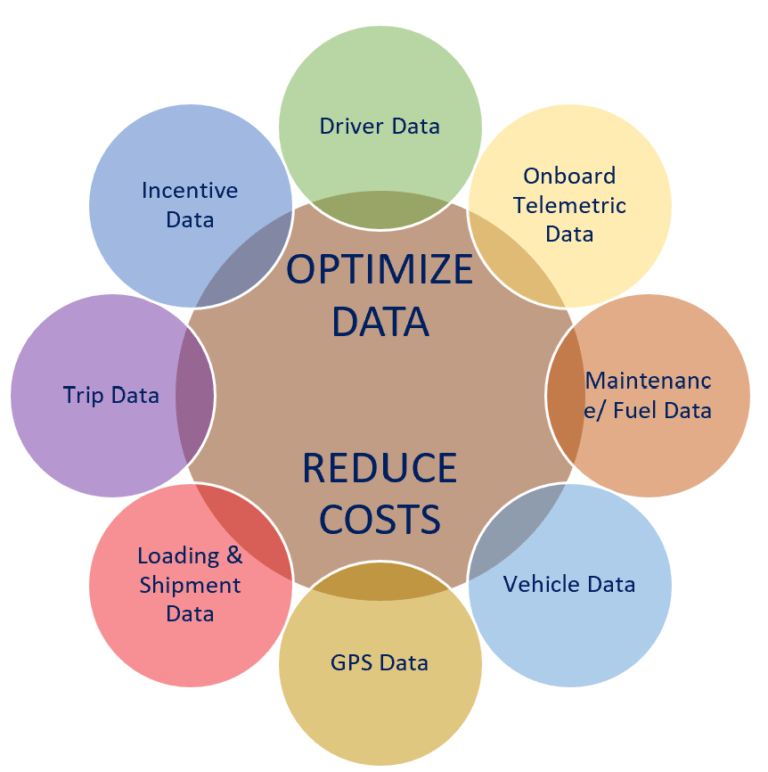

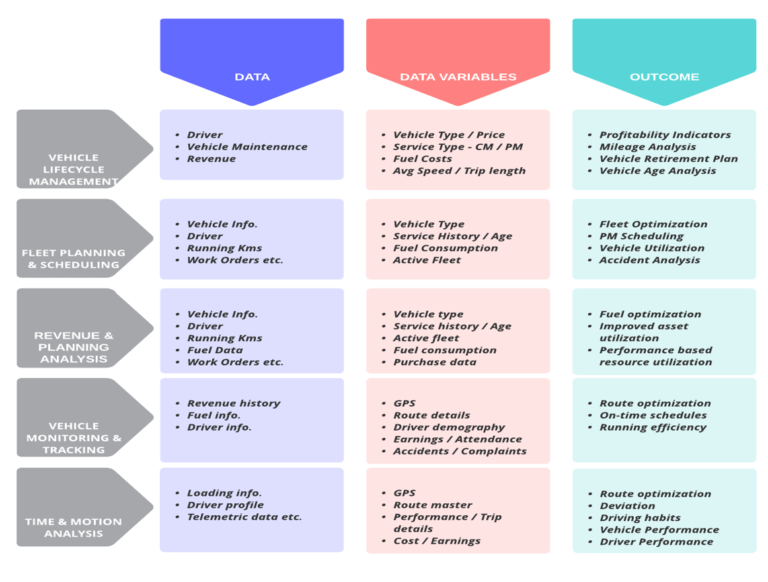

Organizations need not have only a VRO solution in mind. Other KPIs that can be tracked alongwith route optimization depending on their business priorities / pains is outlined in the chart given below:

VRO solution, if complemented by IoT can help you track, report and make changes to the route on the fly. There are numerous other benefits that IoT sensors can bring such as maintaining vehicle quality by monitoring engine performance or tracking tire and brake quality and in some cases, conserving fuel by tracking driver habits or vehicle idle time. In other cases, identifying driver performance if there are sudden stops / starts or speeding. The permutations and combinations in this regard are endless.

In summary, a VRO solution works across different industry verticals and provides immense benefits we have seen above. The modeling approach taken to design such a solution depends on the business pain under consideration. In our example we have shown how Heuristic Algorithms can be used effectively in optimizing and simulating fleet operations and achieving cost efficiencies!

Parag Penker

GLOBAL VICE PRESIDENT – TECHNOLOGY (BIG DATA, DATA WAREHOUSING & BUSINESS INTELLIGENCE)

Parag is heading the Big Data, Data Warehousing and BI initiatives across the USA, India, Middle East and Africa. Parag carries more than 25 years of experience in the IT Industry and has PMP, Oracle Hyperion and SAP Supply Chain Certifications to his credit.