The oil and gas industry, despite its early adoption of technology, has failed to fully capitalize on digital innovations to address its pressing challenges. Amidst fluctuating prices, investor uncertainty, and growing sustainability concerns, there is a crucial need for a paradigm shift. With outdated infrastructure and processes struggling to keep pace, leaders in the oil and gas industry are seeking ways to improve efficiency while meeting sustainability goals.

How can oil and gas enterprises enhance their performance and maintain profitability? The Digital Oilfield offers a solution—a modern approach that utilizes real-time data, automation, and advanced analytics to streamline oilfield operations. This approach not only addresses the industry’s toughest problems but also paves the way for more efficient, sustainable, and cost-effective practices.

Let’s explore how the Digital Oilfield has driven digital transformation in oil and gas by modernizing operations and accelerating innovation through advanced digital technologies.

The Digital Oilfield Explained: Key Technologies and Components

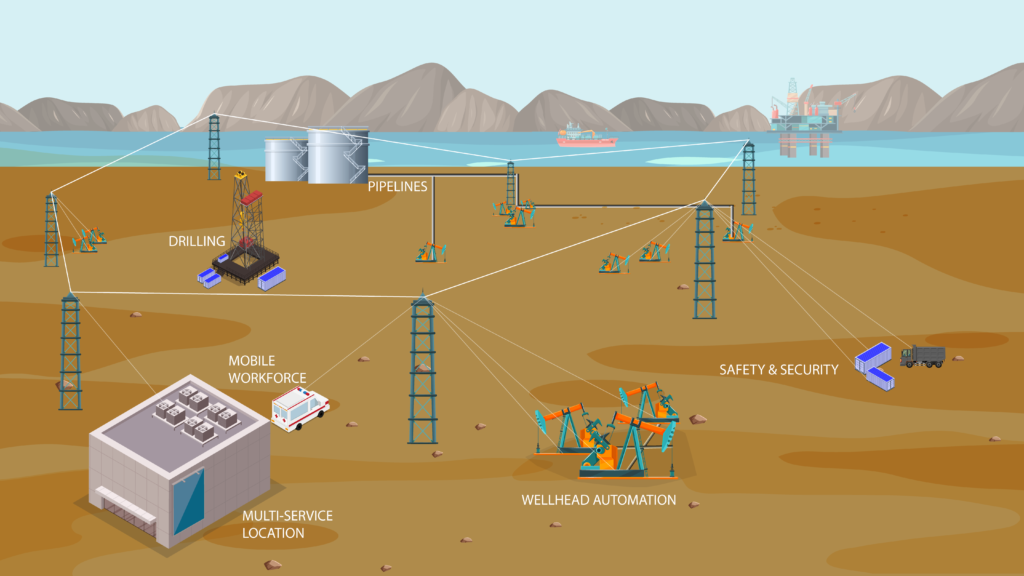

The Digital Oilfield (DOF) leverages digital technologies to improve the efficiency, safety, and profitability of oil and gas operations. It combines real-time data collection, advanced analytics, automation, and remote operations to optimize the performance of oilfield assets.

Key components of a Digital Oilfield include:

- IoT Sensors and Devices: These gather real-time data from various assets such as wells, pipelines, and drilling equipment.

- Big Data Analytics: Processes large volumes of operational data to support better decision-making.

- Artificial Intelligence (AI) and Machine Learning (ML): AI/ML models predict equipment failures, optimize production, and streamline workflows.

- Cloud Computing and Edge Devices: Enable remote data storage, processing, and real-time analysis even in remote oilfield locations.

- Automation: Reduces the need for human intervention, improving efficiency and minimizing human error.

From Digital Oilfield 1.0 to Digital Oilfield 3.0: The Evolution of Oil and Gas Innovation

The evolution of the Digital Oilfield can be traced through three major phases:

Digital Oilfield 1.0: The Early Years

Digital Oilfield 1.0, which emerged in the early 2000s focused on technologies like wireless communications, real-time data streaming, and the initial deployment of IoT sensors. These technologies, including wireless sensors, allowed operators to monitor remote sites and equipment more effectively, while web-based platforms provided real-time access to production data enabling faster decisions and providing greater operational visibility. However, despite the benefits, the technologies were costly and challenging to implement on a large scale.

Digital Oilfield 2.0: Expanding the Digital Frontier

As the industry entered the second phase, Digital Oilfield 2.0, the focus shifted toward workflow automation, advanced modeling platforms, and improved data management. Real-time collaboration centers were created, enabling global teams to analyze production data simultaneously. The introduction of data lakes and big data analytics helped O&G companies manage the ever-growing influx of operational data. However, adoption was slow due to the industry’s conservative nature and the absence of a clear strategy for scaling pilot projects into full-scale operations.

Digital Oilfield 3.0: The Present

Digital Oilfield 3.0 is characterized by integrating advanced technologies such as AI, machine learning (ML), and IoT. These technologies enable real-time monitoring and decision-making, leading to increased efficiency and reduced downtime. AI-based predictive maintenance, smart automation, and digital twins are becoming central to improving productivity, reducing costs, and addressing environmental concerns, such as methane emissions. DOF 3.0 allows for greater optimization across the entire value chain—from exploration to production—while addressing complex challenges like asset integrity and drilling efficiency.

Driving Innovation: How the Digital Oilfield is Shaping Oil and Gas Operations

The Digital Oilfield is driving significant transformation in the O&G industry by enhancing efficiency, reducing operational risks, and improving overall production performance. Below are key areas where its impact is being felt:

Enhanced Operational Efficiency

Leveraging real-time data has enabled O&G companies to monitor assets, detect issues before they escalate, and optimize production. For instance, AI-powered predictive maintenance has the potential to forecast equipment failures, enabling timely repairs and reducing the likelihood of costly downtimes.

Improved Reservoir Management

Digital oilfields have facilitated better reservoir characterization and management. AI-driven reservoir models, with their ability to provide deep insights into subsurface conditions, have the potential to optimize hydrocarbon recovery, enabling more efficient extraction, reducing environmental impact, and extending asset lifespan.

Cost Reduction and Production Optimization

DOFs have demonstrated a high return on investment (ROI) by lowering capital and operating costs. Automation and AI have helped reduce manual tasks, optimize drilling operations, and improve energy management, collectively enhancing production efficiency and profitability.

Sustainability and Environmental Impact

Amid growing pressure to meet decarbonization goals, the oil and gas industry is turning to digital technologies like AI-based methane tracking and emission management systems. These innovations enable companies to monitor and reduce greenhouse gas emissions, particularly methane, meeting environmental regulations more effectively.

Safety and Risk Management

The adoption of digital technologies has significantly enhanced the safety of oilfield operations by minimizing human error. Automation tools, remote monitoring, and real-time data analytics has enabled companies to predict hazardous situations, prevent blowouts, and ensure better asset integrity management.

Digital Oilfield Adoption: Navigating Implementation Challenges

While the benefits of Digital Oilfields are clear, its implementation presents several challenges:

High Costs of Deployment

The cost of implementing digital solutions such as IoT sensors, cloud infrastructure, and data analytics platforms can be prohibitively high, particularly for smaller operators. Deploying wireless communication systems and sensors in remote offshore fields, where trenching and installation are complex, adds to the cost burden.

Cultural Resistance and Knowledge Gaps

One of the major hurdles is the conservative culture of the O&G industry, which is often risk-averse when adopting new technologies. Moreover, a lack of skilled personnel, such as data scientists and digital specialists, further delays the adoption of digital solutions. Bridging the knowledge gap between traditional petroleum engineers and digital technologists remains a critical challenge.

Cybersecurity Concerns

The growing reliance on cloud-based solutions and remote data collection raises concerns about data security and cyber threats. Oil and gas companies are often hesitant to fully embrace cloud technologies due to fears of data breaches, intellectual property theft, or the exposure of sensitive operational data.

Data Management and Integration

Digital Oilfields generate vast amounts of data from multiple sources—sensors, SCADA systems, drilling logs, etc. Integrating this data into a unified system that provides actionable insights remains a challenge. Additionally, data quality and consistency issues often arise, complicating the analytics process.

Interoperability of Systems

The O&G industry relies on a multitude of legacy systems and technologies, many of which do not easily integrate with newer digital solutions. Ensuring system interoperability across different stages of oil production—from drilling to processing—remains a critical issue for many operators.

Future Outlook: Paving the Way Forward with Digital Oilfield Solutions

Looking ahead, the Digital Oilfield is set to redefine industry standards with its continuous monitoring and real-time data-driven insights. Much like the revolutionary advancements in control and automation seen in space exploration, this technology promises to drive unprecedented efficiency and sustainability in oil and gas operations. Embracing these innovations will be crucial for companies to stay competitive and tackle future challenges. To discover how you can leverage Digital Oilfield solutions, contact AppsTek Corp and take the next step toward the oil and gas transformation.