Globally, the manufacturing industry is witnessing substantial growth, sustained by significant investments in semiconductor and clean technology manufacturing, which have seen an unprecedented rise since 2019. As of mid-2023, the sector has seen a 70% year-over-year increase in construction spending, reaching US$201 billion and setting the stage for further expansion in 2024. According to Deloitte Insights, 2024, despite this growth, manufacturers face economic uncertainties, skilled labor shortages, and supply chain disruptions, necessitating a shift towards digital transformation and smart factory solutions to remain competitive.

At a time when the manufacturing industry stands on the brink of a radical shift, the advent of new digital and operational technologies is heralding unprecedented levels of agility, flexibility, and insightful knowledge. This transformation, often encapsulated in ‘Manufacturing 4.0’ or ‘Industry 4.0’, sparks excitement and skepticism among manufacturing executives worldwide. For some, it remains an enigmatic challenge; for others, it’s seen as the latest entry in the lexicon of marketing buzzwords.

Despite the divergent opinions, there is a general consensus on the benefits these technologies bring—predictive maintenance, remote operations, and real-time optimization—signifying a transformative impact on business outcomes.

Manufacturing 4.0 signifies the current wave of automation and data exchange innovations in manufacturing technologies. It integrates cyber-physical systems, the Internet of Things, and cloud computing to forge “smart factories,” marking a significant leap toward Industry 4.0.

Embark on a journey with us as we delve into the critical facets of manufacturing modernization, delivering a comprehensive roadmap and strategic insights to guide you through the intricate layers of digital transformation.

Pivotal Issues of Legacy Systems in Manufacturing

Legacy software modernization in manufacturing enterprises is fraught with challenges that can significantly impact operational efficiency and financial performance. Among these challenges, three critical issues stand out: data integrity & migration, operational downtime, and integration issues. Let us discuss these in detail below:

Data Integrity & Migration: At the core of any manufacturing operation lies its data, encompassing everything from supply chain specifics to detailed product specifications. Migrating from a legacy system to a more contemporary setup carries the risk of data corruption or loss. This transition is not merely a technical exercise but a strategic move that requires careful planning to ensure data integrity is maintained, ensuring that historical data continues to provide value in new digital environments.

Operational Downtime: The fear of operational downtime is a significant concern for manufacturers considering system upgrades. Downtime not only halts production but can also lead to substantial financial losses.

According to IIoT World, unplanned downtime can cost as much as $260,000 per hour, underscoring the high stakes involved in maintaining continuous operation. Moreover, a Siemens’ 2023 report highlights the escalated downtime costs, now costing Fortune Global 500 companies 11% of their yearly turnover, approximately $1.5 trillion, up from $864 billion two years prior.

Integration Issues: The seamless integration of modern systems with existing legacy systems and other digital tools is crucial for a smooth transition. The complexity arises from ensuring new systems can effectively communicate and work alongside older systems that might still be in operation. This challenge emphasizes the need to adopt open standards and leverage APIs for easier integration, ensuring that the digital ecosystem within the manufacturing enterprise is cohesive and efficient.

The path to overcoming these challenges involves a multifaceted approach. Leveraging platforms that can track machine cycle status in real time and accurately categorize downtime events can provide a deeper understanding of operational inefficiencies. Such platforms enable manufacturers to transition from reactive to predictive maintenance strategies, thereby reducing the frequency and impact of unplanned downtime.

Additionally, investing in digital tools that offer real-time data analysis and insights can help manufacturers pre-emptively address potential issues before they escalate, ensuring a smoother transition to modern manufacturing paradigms and minimizing the disruption caused by system upgrades.

The journey towards modernizing manufacturing systems is complex and requires careful consideration of data integrity, operational continuity, and system integration. By acknowledging these challenges and adopting strategic, technology-driven approaches, which we will discuss in the next section, manufacturing enterprises can navigate the transition more effectively, ensuring they remain competitive in the digital era.

Navigating the Four Levels of Manufacturing Modernization

There are four levels involved in manufacturing modernization; each of these levels will be discussed in the section below:

Level 1: The first level, known as the Plant Floor/Process, emphasizes the critical need for modernizing the factory floor. With a significant number of businesses grappling with a digital skills gap, the challenge extends beyond technological upgrades to encompass a comprehensive workforce upskilling. This level underscores the importance of connecting systems and devices to harness data for insightful outcomes, paving the way for a future-proof enterprise.

Level 2: In the second level, or the first-mile connectivity, aligning inbound supply chains with market demand becomes paramount. Here, many manufacturers are betting on the Internet of Things (IoT) to boost profitability over the next five years, reflecting the industry’s move towards demand-driven production lines. This strategic alignment is crucial for enhancing visibility and achieving predictive performance optimization.

Level 3: In the third level, or Secure Last Mile, the focus is placed on engaging customers through both direct and indirect channels, necessitating an open-channel interface between the factory and points of sale. The trend towards mass customization, as demonstrated by industry giants like BMW, is a testament to the sector’s readiness to embrace flexible production lines. This readiness is further highlighted by the fact that 76% of senior executives prioritize automation, according to insights from Forbes, indicating a shift towards more personalized and efficient manufacturing processes.

Level 4: In the fourth and final level, known as the Integrated Enterprises, the aspiration is for a seamless digital tapestry across all organizational functions. The smart market factory industry is expected to be worth USD 86.2 billion in 2022 and is estimated to grow to a whopping USD 140.9 billion by 2027. This represents a Compound Annual Growth Rate (CAGR) of 103%, showing the industry’s strong focus on digital innovation, as per the report by Markets and Markets. This level of digital integration aims for early visibility into disruptions and centralized KPI monitoring facilitated by cloud technologies connecting plants across different geographic regions.

However, the journey through these levels is fraught with challenges, especially since most manufacturers cite supply chain bottlenecks as key digital transformation obstacles to the overarching need for a strategic approach to digital adoption. Yet, the digitization drive, accelerated by the COVID-19 pandemic, with most global enterprises fast-tracking their digital efforts, underscores the urgency of this transformation.

In essence, the manufacturing industry’s digital transformation is a multi-level journey that intertwines technological, operational, and strategic threads. It demands a nuanced understanding of the digital landscape, a commitment to overcoming barriers, and an unwavering focus on harnessing digital tools for innovation, efficiency, and competitive advantage. As manufacturers navigate from foundational modernization to enterprise-wide digital integration, the blend of challenges and opportunities shapes a future where adaptability, foresight, and technological proficiency define industry leaders.

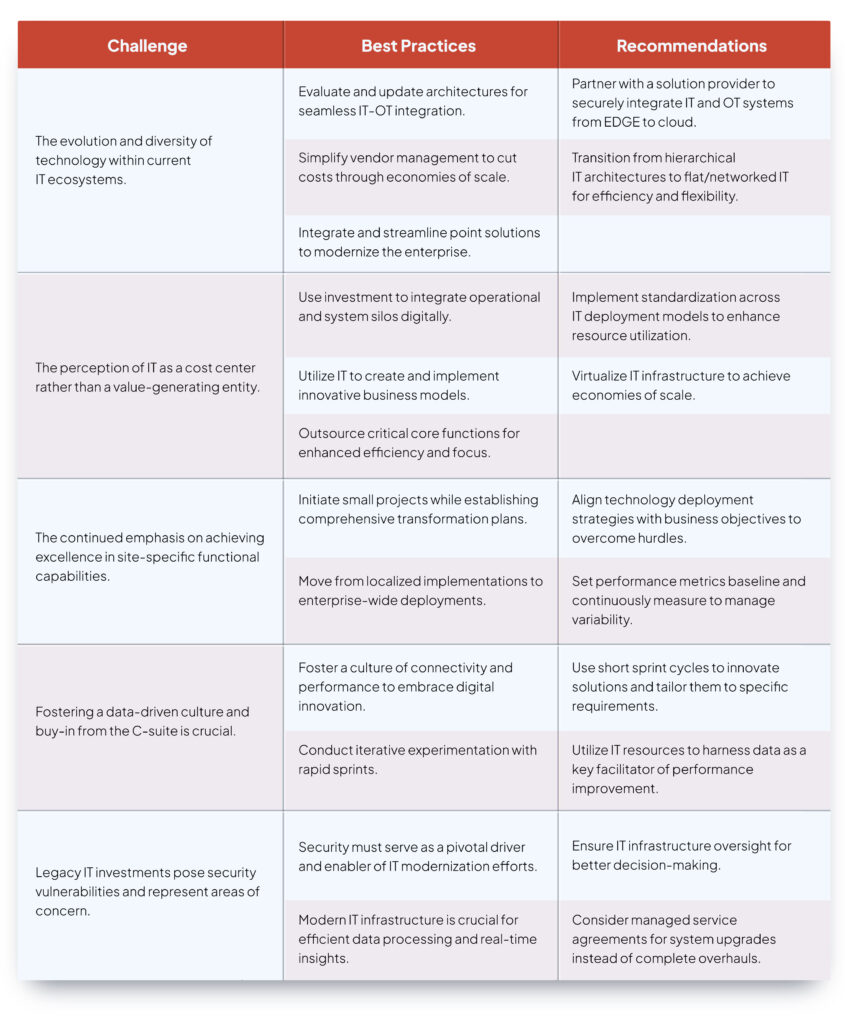

Strategies for Manufacturing Modernization Excellence

Conclusion

As we conclude, the manufacturing sector is at a transformative crossroads, driven by the need for digital innovation and the advent of Industry 4.0. Digital adoption is crucial for competitive edge. This blog has highlighted the challenges of moving from legacy to digital frameworks, focusing on the need for data integrity, operational continuity, and integrated systems.

By adopting strategic digital strategies, manufacturers can address these challenges, leveraging technology to enhance efficiency and value. The insights offered provide a roadmap for digital transformation, guiding businesses towards an innovative and resilient future.

To delve deeper into application modernization for manufacturing industries, connect with experts at AppsTek Corp today.